Hullmatic

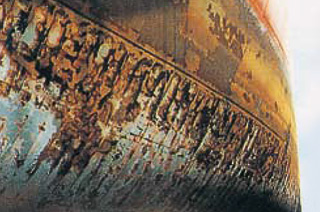

Hull Protection

Impressed current systems were developed originally to protect the underwater external hulls of large tanker and buk carries which could not be satisfied adequately by sacrificial anode systems. Impressed Current Cathodic Protection on ICCP systems are so successful, that they are now commonly used on smaller vessels such as passenger ships and fast container vessels.

SKCP's Hullmatic ICCP systems are in world-wide use in over two thousand vessels; from ULCCs to river tugs and supply boats.

Hullmatic Benefit

- Longer intervals between drydockings reducing operating costs

- Minimum time and cost for maintainance

- Fully automatic operation giving optimum hull protection

- Better long-term hull protection than sacrificial anode systems

- Minimum frictional resistance on the hull

- Constant hull potential monitoring for continuous protection

- Smaller and lighter than any other anode

How Hullmatic Work

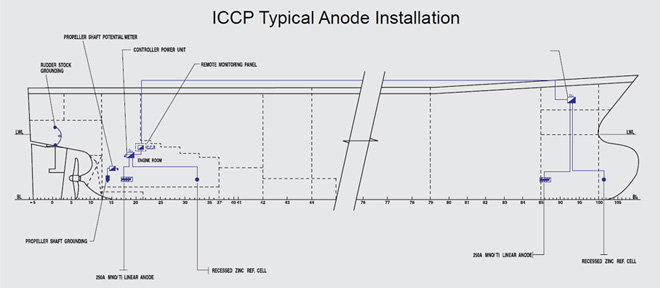

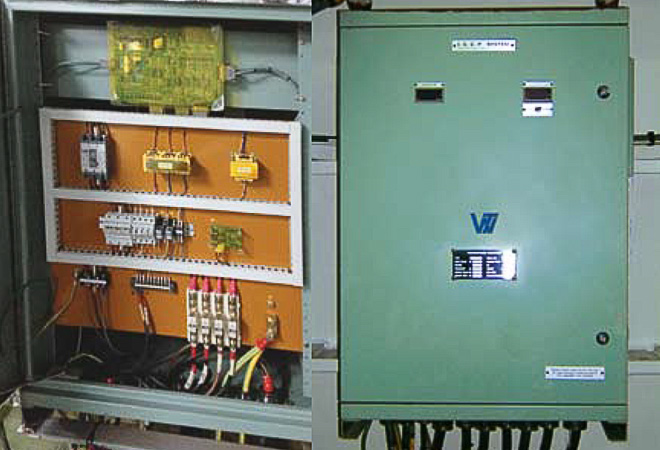

Hullmatic's power unit and control center is it's heart. It receives signals from either zinc or silver/silver chloride reference electrodes mpunted on the hull and automatically controls the current output to inert anodes of platinised or mixed metal oxide titanium or platinised niobium.

Potentials of the hull, prepellor and shaft are neasured against SK Cathodic Protection Services pre-set reference electrodes and fed to the control centre which detects the largest variation. i.e. the area of lowest protection. The control centre, which operate on three-phase AC, in orde to rnsure a balanced load on the generator plant and a smooth DC output, then adjusts the current output in order to provide the optimum level of protection at all time.

Under special operational conditions, it may be necessary to alter the level at which protection starts, or adjust the maximum current output; with Hullmatic this is simple.

The Hullmatic ICCP system has a built in fail-safeon AC and DC and can sustain a full short-circuit on DC without anycomponent damage.

SK Cathodic Protection Services provide daily log sheets giving a continous record of protection levels. Hullmatic is accepted by the main classification societies.

Anodes

Hullmatic uses one or both of two standard types of linear anode; low output and high output mixed metal oxide titanium.

The kinear type is a titanium half tube, unique to SK Cathdoic Protection Services and smaller and lighter than any other manufacturers' linear anode yet does not compromise on output efficiency.

The two standard linear anodes may be installed on all types of vessels where anodes are postioned close to the engine room. All hull-mounted anodes need to be surrounded by a dielectric shield to distribute the current evenly across the ships' hull low output anodes use either sheet of glassreinforced resin on a steel dpuble plates, or a trowel-on mastic. High output anodes use smaller double plates to attach the anodes and trowelon mastic for a large dielectric shield.

In larger vessels, auxiliary anodes may be installed close to yhe fore peak to ensure full bow protection. Those anodes mounted in the forepeak are normally recessed into the hull and are disc or ellipttical made of platinised or mixed metal oxide titnium or platinised niobium, encapsulted in epoxy resin. Since the hull is cuved at this point, a trowel-on mastic dielectric shield is used.

For all anodes, hull penetration kits include a watertight cofferdam assembly with double gland sealing, approved by all major Classification Societies.

Installation and Maintenance

SK Cathodic Protection Services has representation in all the major shipping centres of the world, so that trained engineers are available to discuss installation procedures, supervise work. commission systems and supply services. In the South East Asia region, including China and Hong Kong, our own trained persommel carry out the required work.

On existing vessels, hull components can be installed during dry docking and also the electrical components either during the dry docking or subsequently.

(Once Hullmatic®is commissioned, it is fully automatic and no adjustment to any of the controls is normally necessary.)